- TRUNNION BALL VALVE

- CAST TRUNNION BALL VALVE (Splited body, side-entry)

- FORGED TRUNNION BALL VALVE (Splited body, Fixed-shaft structure)

- FORGED TRUNNION BALL VALVE (Splited body, Support plate structure)

- DOUBLE BLOCK AND BLEED VALVE

- FULL WELDED BALL VALVE

- TOP ENTRY BALL AVLVE

- CONFIGURATION OF BALL VALVE DRIVING DEVICE

FORGED STEEL FLOATING BALL VALVE(FORGED)

-

Share:

Nominal diameter(in): NPS 1/2ˇ8

Nominal pressure(Class): Class150ˇClass600

Design and manufacturing: API 608

Face-to-face dimensions: ASME B16.10

Pressure test: API 598

Transmission mode: Manual, worm and worm gear transmission, pneumatic, electric

Description

DESIGN STRUCTURAL FEATURES

1. Seat Design

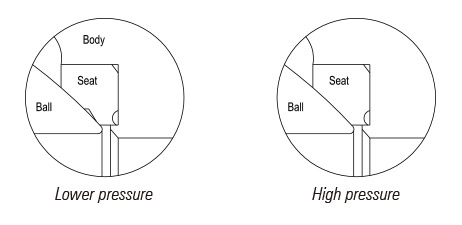

The floating ball valve adopts the design of flexible seal ring structure. When the medium pressure is lower,the contact area of seal ring and ball is smaller,so higher sealing ratio is formed at the place where the seal ring and ball contact to ensure reliable sealing. when the medium pressure is higher,the contact area of seal ring and ball becomes bigger along with the elastic deformation of seal ring , so the seal ring can endure higher medium thrust without being damaged.

Elastic Seat

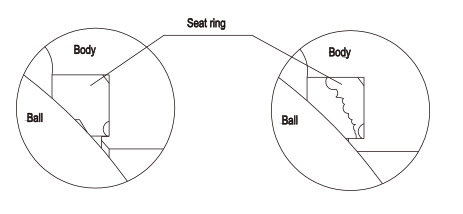

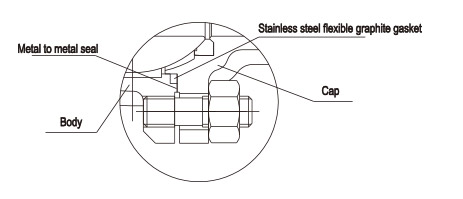

2. Fire-safe Design Structure

In case of fire during the use of valve ,the seat ring made of PTFE or other non-metal materials will be decomposed or damaged under high temperature and cause higher leakage. The fireproof seal ring is set between ball and seat so that after the valve seat is burnt,the medium will push the ball rapidly towards the downstream metal seal ring to form the auxiliary metal to metal sealing structure, which can effectively control valve leakage.In addition,the middle flange sealing gasket is made of metal wound gasket, which can ensure sealing even under high temperature. The fireproof sructure design of floating ball valve conforms to requirements in API 607,API 6FA,BS6755 and other standards.

Fire-safe design structure of seat

Fire-safe design structure of middle flange

Fire-safe design structure of stem

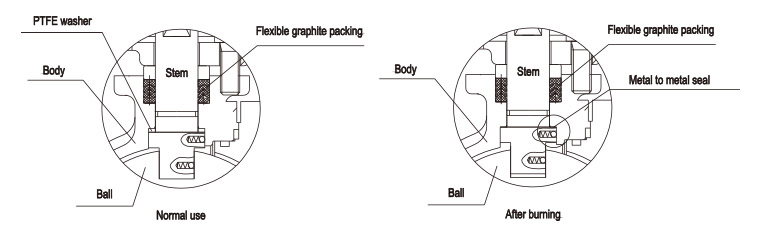

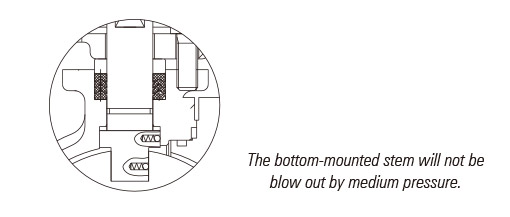

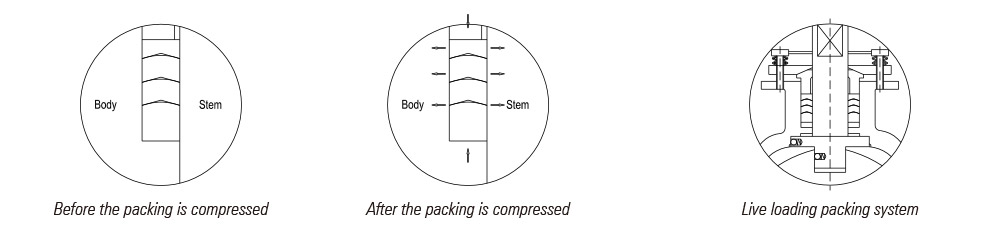

3. Reliable stem sealing

The stem is provided with the shoulder at its bottom so that it will not be blown out by the medium even under the extreme conditions sush as abnormal pressure rise inside the valve cavity, failure of gland plate and etc.In addition, to avoid leakage after the stem packing is burnt in case of fire,the thrust bearing is set at the place where the stem shoulder and body contact to form a reverse sealing seat. The sealing force of the reverse seal will increase according to the the increase of medium pressure, so as to ensure reliable stem sealing under various pressure, prevent leakage and avoid accident spreading.

The stem adopts V type packing sealing structure. The V type packing can effectively change the pressing force and medium force of the glad into the sealing force of the stem. According to user requirements,the disc spring loaded packing pressing mechanism can be adopted to make the sealing of stem packing more reliable.

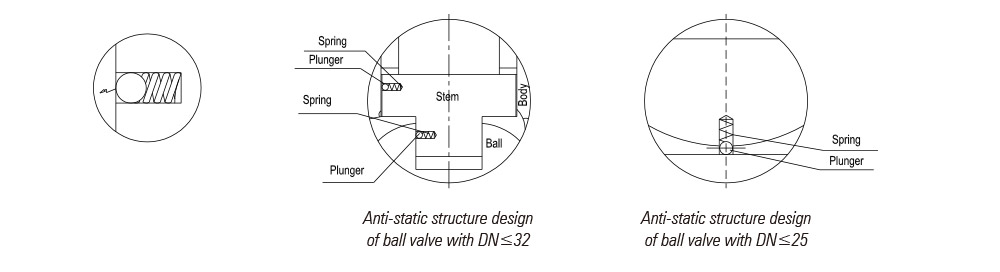

4. Anti-static design structure

The ball valve is provided with the anti-static structure and adopts ths static electricity dis-charge device to directly form a static channel between the ball and body or form a static channel between the ball and body through the stem, so as to discharge the static electricity produced due to friction during theopening and closing of ball and seat through the pipeline, avoiding fire or explosion that may be caused by static spark and ensuring system safety.

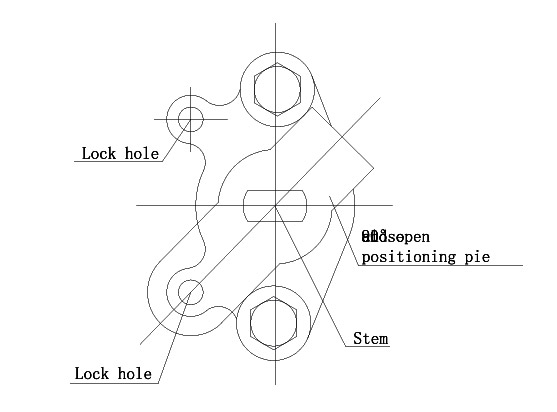

5. Lockable design & Misoperation Prevention structure.

The manual ball valve can be locked by a lock when it is at the full open or full close position, The 90 open and close positioning piece with lock hole is designed to avoid valve misoperation caused due to handle operation by non-operators, and it can also prevent valve opening or closing,or other accidents caused by pipeline vibration or unpredictable factors. It is very effective especially for inflammable and explosive oil, chemical and medical working pipelines or field tubing. The part on the head of the stem that is installed with the handle adopts flat design.When the valve is opened, the handle is parallel to the pipeline, and when the valve is closed, the handle is vertical to the pipeline, so that the opening and closing indications of the valve are guaranteed to have no error.

Lockable design & Misoperation Prevention Structure

Send Inquiry

Please feel free to contact with us at sales@leadervalve.com.cn or filling up an enquiry form instructed at the bottom, You will get an effective response within 24 hours from Our sales representative. Thanks for your valued time with interest!